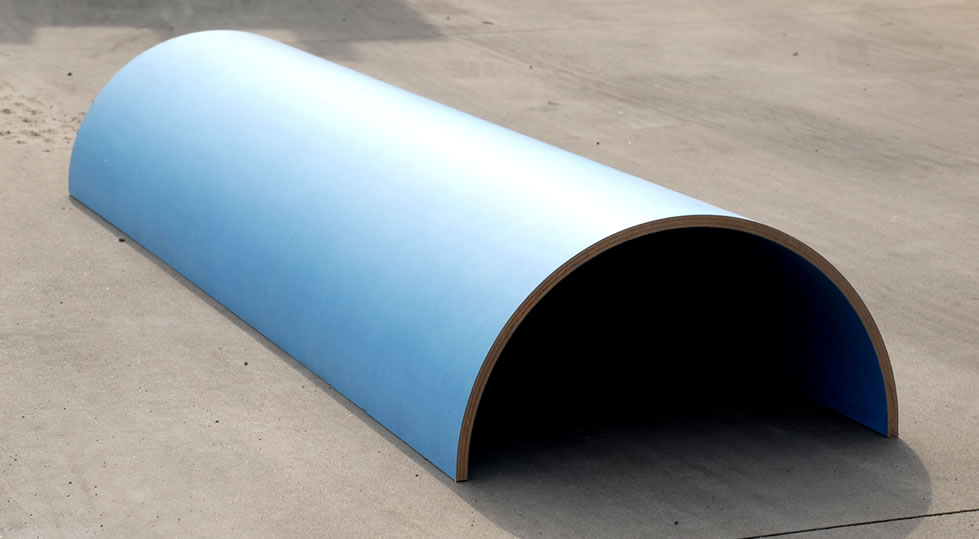

Rotary Plywood

Seaga Group provides the widest range of beech shells in the market: the offer really includes all shells with diameter from 174 to 700 mm, with incredible possibilities of customizing respect the high, external semicicircle length and surface.

1. The production of great rotary shells starts from the selection of best beech logs from east-european forests: the entire productive process from the log treatment to the final packaging is managed inside the company production plant. Thanks to the strict quality control on all processing phases Penta Box is able to deliver the ideal product for today work habits of die makers all over the world.

2. All the processing phases are projected to obtain 100% beech rotary shells with the best possible wood stability to respect tight dimension tolerances and minimize the placing time for the cutting phase.

3. The temperature and humidity parameters during the curving process are strictly controlled for each range of shell diameter. The shells are trimmed with the customer specification with electronic controlled cutting system.

QUALITY CONTROL

Each shell is marked with:

- Operator identification number, week and year of production

- Number of trimmer operator and machine

- Diameter tolerance check in 3 different points

PRODUCT RANGE

| DIAMETER RANGE | 170 – 750 mm (6 ½‘’ – 29 ½ ‘’) |

| LENGTH | Up to 3000 mm – depending to diameter (118 1/10’’) |

| TICKNESS | 12,7 – 18 (1/2’’ – 7/10’’) Special thickness available on request |

| TRIMMING |

|

| SURFACE |

|

TECHNICAL DATA

| DIAMETER TOLERANCES | 170 – 242 -2/+2 (6 ½‘’– 9 ½’’ -2/25’’ / +2/25’’) |

| 243 – 390 -3/+2 (9 3/5’’ – 15 1/5’’ -1/10’’ / +2/25’’) | |

| 391 – 487 -4/+2 (15 2/5’’ – 19 3/16’’ -3/20’’ / +2/25’’) | |

| THICKNESS TOLERANCES | ± 0,3 mm ± 1/100’’ |

| LENGTH TOLERANCES | ± 10 mm ± 2/5’’ |

For pricing or other enquiries please contact us on 03 9450 9500 or email us at sales@seaga.com.au

For pricing or other enquiries please contact us on 03 9450 9500 or email us at sales@seaga.com.au