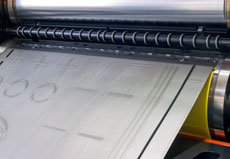

RSP System 2.0

The economical and fast alternative to classic converting of your products. Creasing, diecutting, kisscutting and perforating inline: without an extra machine, without additional personnel or time-consuming processing. Experienced applications engineers quickly and practically familiarise your employees with the RSP System 2.0.

The system is suitable for all kinds of different requirements, starting with simple perforations for reply cards, tear-off cards, coupons and vouchers to window cutting, cutting and kisscutting of adhesive labels, presentation folders and sophisticated mailings and creasing.

The advantages at a glance:

- Reusable and archivable grid sheet and direct flexible dies

- High quality due to optional register adjustment

- Fast change in the machine for consecutive print jobs

- Optimized makeready time of inline finishing jobs in the

printing press - In addition to the grid sheet, it is also possible to mount direct fit flexible dies on the base plate 2.0

Available for the sheetfed offset presses of the following machine producers:

- HEIDELBERG

- KOMORI

- manroland

- Koenig & Bauer

Technical Infos

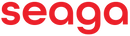

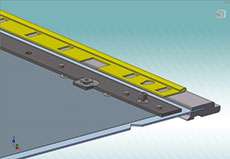

The grid sheet to be used with the RSP System is fixed to the base plate on the printing press. Previously, a three-part system was used on the front and rear edge of the base plate.

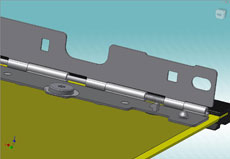

That system has now been replaced by a two-part locking hinge. The bolts needed for fastening the yellow locking bar are no longer required at all, as the new system operates by means of a hinge developed by us specifically for this purpose.

The previous black bolts on the base plate have been replaced by locking hooks, the previous grid sheet bar fastening has been replaced by a newly-designed flat head bolt, and the fixing bar segment has been replaced by the hinge counterpart.

This enables better utilisation of the limited space available on the printing press and reduces the height of the base plate by 30 % in this area, providing significant handling improvement and therefore better ease of use.

The major innovation is the facility to also fix a flexible die directly onto the locking hinge, in addition to the RSP grid sheet.

The RSP direct fit flexible die guarantees best reproducibility of shapes with a maximum level of accuracy.

NOTE

RSP with sheetfed offset printing machines with perfector

It is not possible to use RSP in factories equipped with machines using a Teflon or silicone coating on the impression cylinder. In case of replacement by the respective uncoated alternative of the machine manufacturer use is possible.

RSP with HEIDELBERG sheetfed offset printing machines with perfector

HEIDELBERG PerfectJackets

Use of our RSP on machines equipped with HEIDELBERG PerfectJackets on the impression cylinder is not possible as our protective impression cylinder jackets do not stick on that surface.

HEIDELBERG Mark3 jackets

But RSP can be used if the Perfect Jackets are replaced by HEIDELBERG Mark 3 jackets. These HEIDELBERG Mark 3 jackets are available for all presses with perfecting unit.

RSP with manroland sheetfed offset printing machines with perfector

On machines equipped with OptiPrint Jackets on the impression cylinder use of RSP in the units equipped with these jackets is not possible as our protective impression cylinder jackets do not stick on that surface.

RSP with Koenig & Bauer sheetfed offset printing machines with perfector

Protective impression cylinder jackets with special adhesive tape for silicone jackets are to be used

for machines with silicone jackets on the impression cylinder.